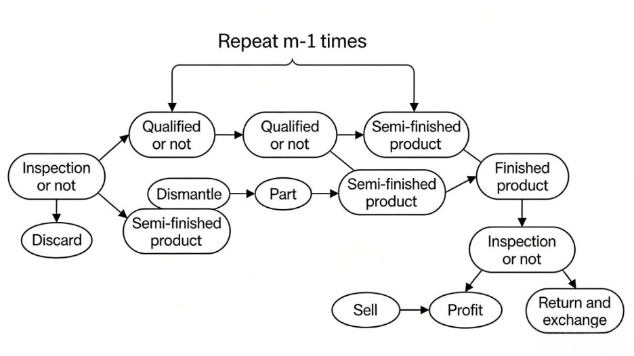

In the field of discrete manufacturing, particularly during electronic product assembly, quality fluctuations and cost control represent core challenges for enterprises. This paper addresses multi-stage production decision-making by constructing an integrated decision model that combines hypothesis testing, unconstrained optimization, and genetic algorithms. This model provides end-to-end support spanning sampling inspection, production process optimization, and robust decision-making under uncertainty.The model aims to maximize average profit by introducing 0-1 decision variables to characterize inspection and processing choices at each stage. It employs hypothesis testing to design minimum sample size sampling schemes, utilizes unconstrained programming for single-process and multi-process production decisions, and leverages genetic algorithms to solve large-scale combinatorial optimization problems. Under uncertainty, it characterizes defect rate fluctuations through confidence intervals, establishes robust decision models, and conducts sensitivity analysis.Numerical experiments demonstrate that the proposed model delivers effective and robust decision solutions across diverse scenarios, providing enterprises with systematic theoretical methods and practical tools to enhance quality control and economic efficiency.